Kayayyaki

API 7-1 Kayan aikin niƙa Sashen Casing

Bayanin samfur

Sashe niƙa wani nau'in kayan aikin buɗe taga ne wanda ke haɗa aikin yankan casing da aikin niƙa. Aikin niƙa na sashe yana shiga cikin casing tare da BHA, kuma yana yanke casing a wurin da aka keɓe da farko. Bayan an yanke kaskon gaba ɗaya, za a niƙa shi kai tsaye daga wannan matsayi. Bayan kai wani zurfin zurfi, aikin buɗe taga casing yana kammala. sashe niƙa yana da abũbuwan amfãni daga cikin sauki tsari, m aiki don sa shi mai matukar tasiri casing taga kayan aiki.

A halin yanzu, injin niƙa na iya matsewa da allurar siminti a cikin aikin watsi da kyau, wanda zai iya yin hulɗa kai tsaye da siminti a cikin nisa mai nisa tsakanin digiri 360. Simintin zai iya shiga cikin tafki bisa ga porosity da kuma karaya na samuwar, kuma tasirin toshewa ya fi na matse siminti bayan huɗa.

Ƙa'idar aiki

Bayan an saukar da injin niƙa zuwa matsayin da aka keɓance a cikin casing tare da BHA, fara teburin jujjuya, kunna famfo, piston a cikin kayan aikin yana tura ƙasa ta matsa lamba, ƙananan mazugi na piston yana tura yankan ruwan wukake da gyarawa. budadden rami. Lokacin da yankan ruwan wukake ya buɗe zuwa matsakaicin diamita, an gama gyara buɗaɗɗen ramin. A ƙarƙashin ci gaba da matsa lamba na famfo, ana iya buɗe ruwan wuka kuma a sake gyara rami kai tsaye. Bayan an dakatar da famfo, za a sake saita fistan a ƙarƙashin aikin bazara kuma za a ja da yankan ta atomatik.

Siffofin samfur

(1) Tsarin injiniya, tsari mai sauƙi da aiki mai sauƙi

(2) Matsakaicin farawa da babban ƙarfin goyan bayan ruwa suna taimakawa ga yanke casing;

(3) Babban ƙarfin ƙirar bazara yana taimakawa ta atomatik ja da mai yanke bayan yanke;

(4) Tsarin toshe tasha da fil yana taimakawa don tilasta janyewar kayan aiki;

(5) Ruwan ruwa yana da babban haɓaka kuma ana iya amfani dashi a cikin akwati ɗaya tare da kauri daban-daban na bango;

(6) The ruwa da aka yi da high quality tungsten carbide da Gasa hughes iri waldi tsari, tare da high yankan yadda ya dace da kuma dogon sabis rayuwa.

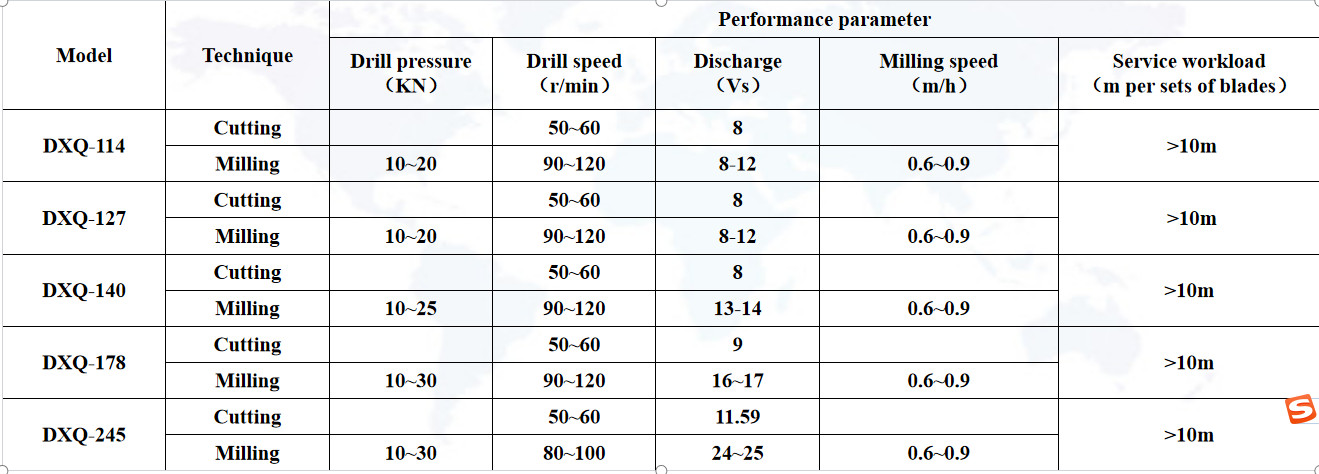

Teburin niƙa-Size-Size

Kayan aikin da suka dace - Babban injin niƙa taper

Kayan aikin niƙa duk an yi su ne da ingantaccen gami da tungsten carbide gami da Baker Hughes fasahar walda iri ɗaya. Manufar wannan jerin niƙa shine don dawo da zaɓin kayan gaba ɗaya, ƙirar tsari da tsarin walda na Baker Hughes, don cimma ƙimar ingancin Baker Hughes iri ɗaya.

2.High class famfo niƙa profile

iya samar da high class taper niƙa tare da waje diamita na 76 mm zuwa 445 mm. Ana amfani da ƙarfe mai inganci mai inganci a matsayin babban jiki, yana ba da damar sarrafa manyan ramukan ruwa don tabbatar da fitar da tarkace mai laushi. A lokaci guda, bisa ga takamaiman bukatun abokan ciniki, ana iya tsara tsarin samfurin don cimma mafi kyawun aikin amfani.

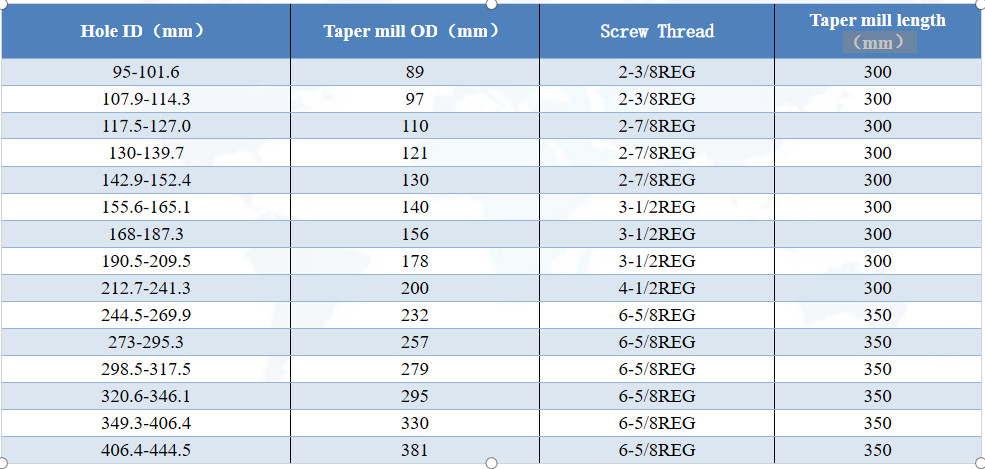

3.Taper niƙa-Size tebur

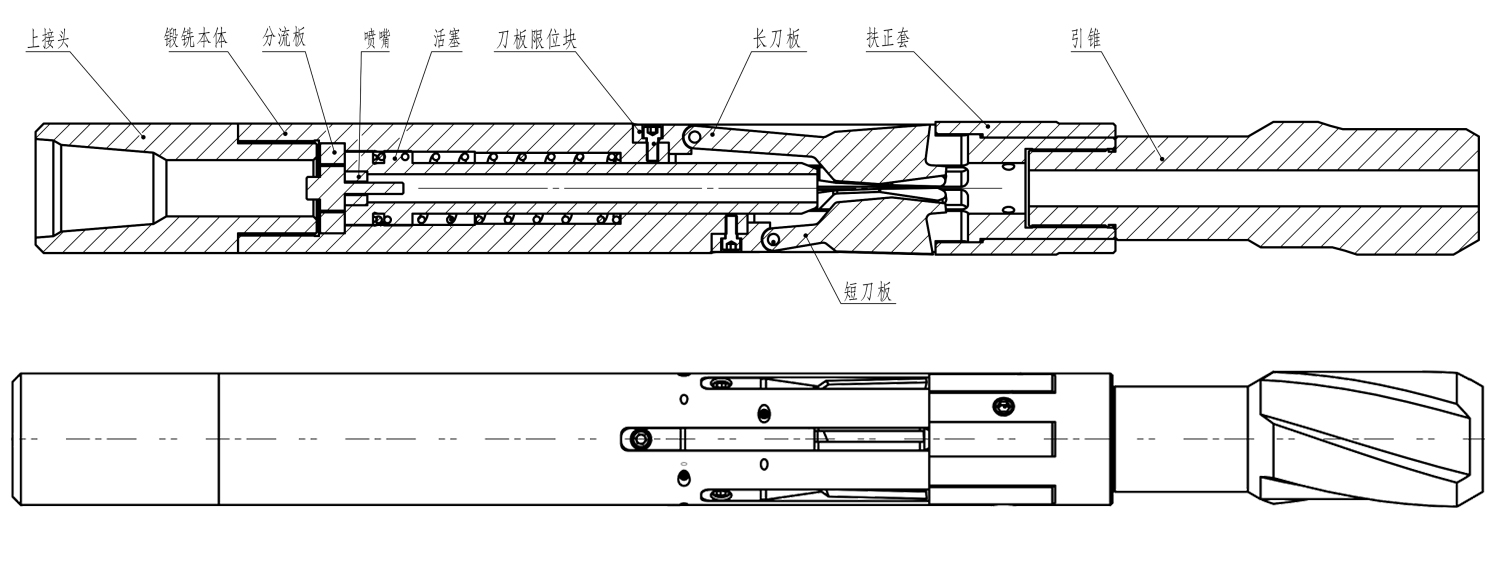

Tsarin samfur

1. Sashin niƙa ya ƙunshi sassa masu zuwa: haɗin gwiwa na sama, babban jiki, piston, bututun ƙarfe, yankan ruwan wukake da mazugi jagora, da sauransu.

III.Fa'idodin fasaha na injin sashe na Petrozhr

1.Samar da high quality tungsten carbide

Wuraren niƙa da kamfaninmu ke samarwa suna da fa'idodi masu zuwa:

(1) Niƙa da yanke ayyukan sun fi sauri fiye da ruwan wukake na yau da kullun;

(2) Rage matsin hakowa da ake buƙata don yanke;

(3) Alamomin haƙori sun kasance ko da kuma ba a samar da saman mataki ba;

(4) tarkacen da aka samar ya fi uniform;

(5) Taurin albarkatun ƙasa ya fi girma kuma tsarin yana da ma'ana. Lokacin aiki, yana yanke ƙarfe maimakon niƙa karfe.

2.Tuntuɓitaccen binciken albarkatun ƙasa

The tungsten carbide zaba da kamfanin mu za a aika zuwa ƙwararrun gwaji hukumar domin dubawa bayan kowane tsari ya zo.Don tabbatar da cewa gami taurin da sauran Manuniya cika da kamfanin ta samar da bukatun.

3. Cikakken tsarin walda

Muna ɗaukar tsohon Baker Hughes babban welder kuma muna zaɓar kayan aikin walda iri ɗaya da kayan taimako a cikin taron bitar Baker Hughes don gane haifuwar fasahar walda ta Becker a cikin tsari da kayan aiki.

Domin rage nakasar kayan aiki saboda thermal canje-canje kafin da kuma bayan waldi, mun kafa walda rufi tsarin don tabbatar da kwanciyar hankali na samfurin lissafi da kuma aiki yadda ya dace.

IV.Section niƙa tsarin aiki

Shirye-shiryen rijiya:

1. Gyara casing. Gyara kwandon bakin rami tare da injin niƙa ko siffar casing.

2. Tsabtace Lafiya. A wanke danyen mai ko wasu ruwaye daga rijiyar da ruwa mai tsafta.

3. Scraving casing ko rijiya. Za a aiwatar da bututun bututu da tuƙi tare da daidaitaccen juzu'i da diamita mai nisa zuwa mita 20 ƙasa da wurin niƙa sashe.

4. Shirya ruwan niƙa. Kaddarorin sa daban-daban na iya tabbatar da ingantaccen ɗaukar ƙarfin ƙarfe zuwa tarkacen ƙarfe.

Gwajin ƙasa:

1. Gwada amincin kayan aikin;

2. Ana gwada canjin matsi na famfo lokacin da aka buɗe yankan ruwan wukake, wanda ke ba da tushe don yin hukunci ko an yanke katakon ƙasa gaba ɗaya.

Zaɓin matsayi na niƙa:

1. Simintin da ke waje da sashin niƙa ya kamata ya kasance da siminti da kyau.

2. Kauce wa wuri inda rumbun ke da tarwatsewa da nakasa. Idan akwai irin wannan matsayi, ya kamata a gudanar da aikin 30-40m sama da matsayi. Kuma farkon aikin yankewa zai kasance 1-3m sama da haɗin gwiwa mafi kusa.

3. Ya kamata a ajiye aljihu a ƙarƙashin shaft. Gabaɗaya, tsayin aljihu ya kamata ya fi 100m.

Yanke akwati:

① Bayan haɗa kayan aiki zuwa cikin BHA kuma ta gangara zuwa matsayi na niƙa, fara tebur na jujjuya don tantance matsayi na haɗaɗɗen casing bisa ga rikodin casing (logging), kuma rage kayan aiki zuwa kusan 1-3m sama da haɗin gwiwa mafi kusa da birki. .

② Fara teburin juyi na farko, ƙara saurin jujjuya zuwa 50-60r / min, fara famfo, ƙara haɓakawa a hankali, don haka ƙarfin famfo yana ƙaruwa. A wannan lokacin, matsa lamba na famfo yana ƙaruwa daga ƙarami zuwa babba, a hankali yana ƙaruwa zuwa 10-12mpa.

③ Ci gaba da yanke casing na 20-45min. Lokacin da famfo matsa lamba ya faɗi ba zato ba tsammani da 2-5mpa, an yanke casing. Domin sanya jikin mai yankan ya buɗe sosai, ajiye wurin yanke a wannan matsayi na tsawon mintuna 30 bayan yanke, sannan a hankali ƙara ƙaura don tabbatar da samuwar karaya.

Nikakken akwati:

Ana iya ƙara WOB a hankali bayan an yanke murhun. wanda ake sarrafawa tsakanin 10-25kn, ana ƙara saurin jujjuyawar zuwa 80-120r / min, kuma ana sarrafa matsin famfo a cikin 10MPa don tabbatar da cewa ƙaurawar kewayawa na iya ɗaukar tarkacen ƙarfe. Lokacin da kowane sashe ya kai 0.5m, ana iya hako shi 1m don reaming ɗaya da zagayawa, don sauƙaƙe tarkacen ƙarfe da aka niƙa daga sashin don dawowa lafiya ta hanyar annulus. Bayan zagayowar 1-2, sake yin rawar jiki don ci gaba da ƙirƙira da niƙa.

[A cikin tsari, wajibi ne don daidaita aikin laka daidai yayin da ake ƙara ƙaura; a lokaci guda, da kyau motsa kayan aikin hakowa da daidaita yanayin wurare dabam dabam don sa kwakwalwan ƙarfe ya dawo gabaɗaya kuma ya hana tara tarkace]

Dakin 703 Ginin B, Cibiyar Greenland, yankin bunkasa fasahar Hi-tech Xi'an, China

Dakin 703 Ginin B, Cibiyar Greenland, yankin bunkasa fasahar Hi-tech Xi'an, China 86-13609153141

86-13609153141